DOM diamant half cylinder

Everlasting quality

The DOM diamant system impresses with extreme performance values. Here you can experience the high quality of another generation - made by DOM. The diamant system allows far higher requirements for protection and locking comfort. This is made possible by the steel locking mechanism with 21 rotating steel discs. Every single component, from the material to the locking mechanisms, stands for uncompromising quality down to the last detail.

Basic length:

- from 32/10 mm

- measured from the middle of cam

- extension in 5 mm steps

Technical characteristics:

- highest drilling and core pulling protection

- increased drilling protection through carbide elements or steel-hardened elements

- modular construction with chrome-nickel-steel connecting bar

- drilling protection according to VdS BZ+ as standard

- 21 rotating, ball bearing mounted steel discs

- 35-fold locking authorisation queries per key

- 2 upstream inspection discs

- 3 axially arranged locking rollers

- coreless locking system

- 10 rotating locking elements (freely rotating, stainless steel locking segments)

- 6 massive pin locking elements

- lateral revision pins

- locking security class according to DIN EN 1303 04/2005: 6

- 10 years DOM additional guarantee if registered under DOM

Execution:

- solid cylinder body made of high-quality stainless steel in MIM technology

- cylinder core: duracast

- corrosion-free and low-wear

Key:

- key thickness: 6 mm

- highest key copy protection through multilinear, three-dimensional key profile, CNC manufactured

- stainless steel key with duracast bow

- ergonomically shaped key head, energy-saving door opening

Options / Special equipment:

- different cylinder finishes (polished brass, oxidized bronze)

Operational area:

- external doors, additional cylinder for front doors with increased security requirements

- garages

- single-family homes with the highest protection requirements

- airports, educational institutions, financial buildings, residential buildings, hospitals, industry, hotel buildings

- high security building

- small to large companies

Care instructions:

The DOM diamant cylinders have a disc locking mechanism which must not be lubricated with a solid lubricant (e.g. graphite). They are sufficiently provided ex works with a resin-free liquid lubricant so that their perfect function is guaranteed for a long time. However, to prevent the cylinder from "running dry" during heavy use, it should be "relubricated" from time to time with the DOM Service Spray.

Scope of delivery:

- half cylinder incl. 3 or more keys

- 1 fixing screw

- Security card

Manufacturer:

DOM Sicherheitstechnik GmbH & Co. KG

Wesselinger Straße 10-16

D-50321 Brühl/Köln

www.dom-security.com

MIM Technology

DOM diamant achieves extreme performance values with the innovative disc technology and the cylinder fully encased in high-quality MIM steel. The stainless steel used here is coated with the special MIM process (metal injection moulding), a powder injection moulding process.

Impact protection

The cylinder contains impact protection pins and other safety elements that prevent access by impact keys to turn the inner pins.

Opening protection

The cylinder contains specially shaped unlocking security pins that prevent opening by means of a lock pick.

Pulling protection

The cylinder contains a special cylinder core which prevents the cylinder from being pulled out by drilling into the core.

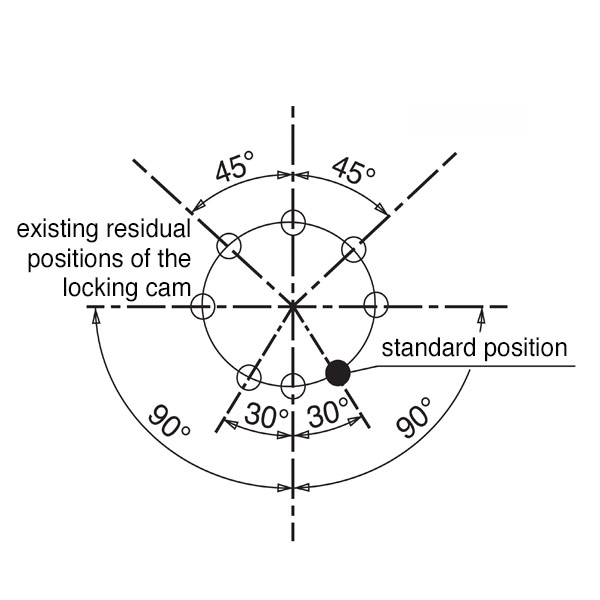

Cam position

The locking cam can be turned to 8 different locking positions (see white circles). The black circle represents the position at which the locking cam is positioned by default.

If you want to change the locking cam, it works as follows:

- Insert the key into the cylinder and turn the cam.

- Press the locking pin in the locking cam with a pointed object

(e.g. the DOM release needle or a thin slotted screwdriver) downwards towards the pressure spring. - Hold the key firmly and then turn the locking cam to the desired position.

- If the adjustment is successful, the locking pin can be heard to engage.

How to measure the cylinder length correctly?

Drilling protection VdS BZ+ = high safety for special requirements

In cooperation with the police, VdS Schadenverhütung GmbH has developed a star system that divides mechanical locking systems into three different security classes, thus providing you with a quick overview of the respective security level.

- drilling protection VdS BZ+ = VdS security class 3

- recognition by VdS Schadesverhütung GmbH

- VdS checks locking systems and awards recognition from A to BZ+

Cylinder finishes:

- surfaces (polished brass, oxidized bronze)

- standard finish: steel/duracast (silver-coloured)

- for individual design requirements

- if desired, homogeneous appearance of door cylinder and fitting

If a different cylinder finish, different from the standard finish, is ordered, extended production times may occur.

steel/duracast

polished brass

oxidized bronze

DOM offers you a free additional guarantee on this system in addition to the DOM guarantee with a total term of 10 years.

To do this, you must register with DOM within 1 month of purchasing the registered single lock.

You can find further information on this at DOM under the following link.