DOM ix Teco® (7TE) half cylinder

System ix Teco® (7TE) "Easy access to superior security"

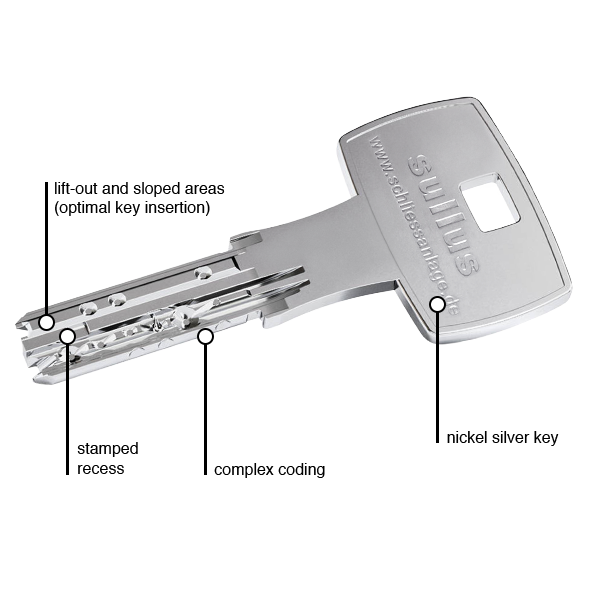

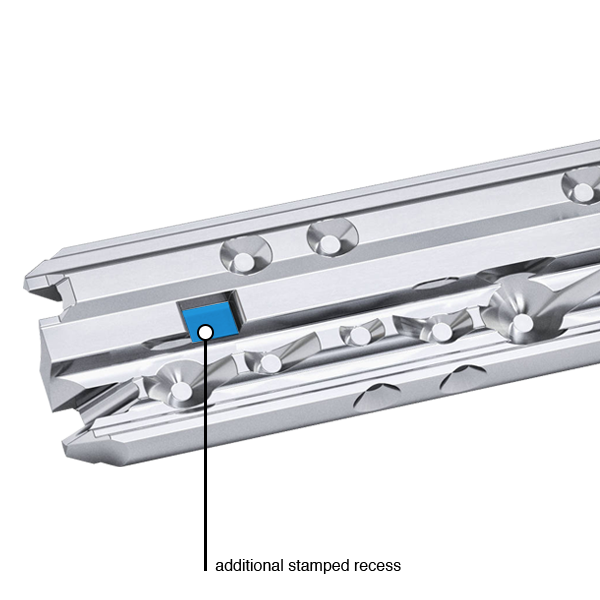

The new ix Teco® reversible key (commercial profile ix 7TE) is particularly well protected against unauthorized copying by an innovative additional stamped recess in the key, based on a patented technology. A special high-low (HT) milling technology in the horizontal base profile increases security during profile control and is difficult to copy. With the innovative and sophisticated design, you acquire a locking system with efficient key copy protection, which is predestined for use in the locking system, but also for individual locks.

Patent protection until 2038

Basic length:

- from 30,5/10 mm

- measured from the middle of cam

- extension in 5 mm steps

- from 75,5/10 mm, the production is carried out in modular design

Technical characteristics:

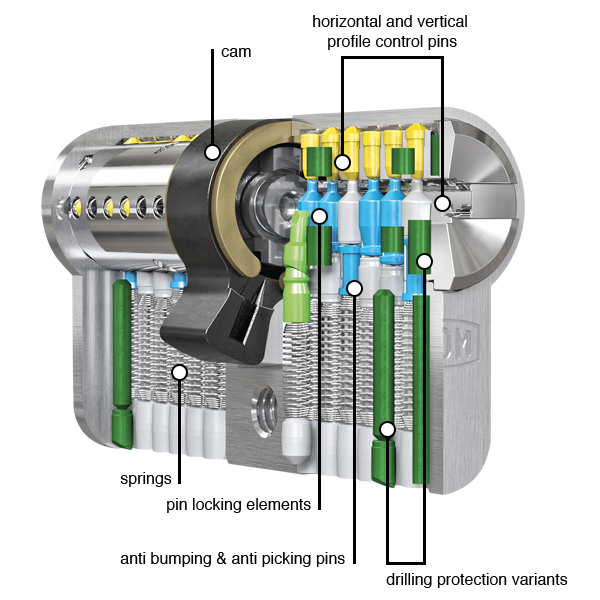

- high protection against manipulation due to 20-fold locking authorisation query

- anti bumping (impact key protection) & anti picking pins (picking protection)

- up to 12 horizontal and vertical profile control pins: control points for the authorization query of a key

- 7 spring-loaded pin locking elements, axially arranged, made of special brass/hardened steel offer manipulation protection (6 variable tumblers, 1 function pin interrogation for the stamped recess)

- 12 core and body pins

- narrowed core and body pins for safety during scanning and unlocking

- drilling protection (standard): 2 hardened steel pins in the body, 1 hardened steel pin in the cylinder core

- 13 mm core diameter

- one-piece cam made of sintered steel

- concave core head as key insertion aid

- according to DIN EN 1303:2015-08, certified according to ISO 9001:2015

- locking security class 6, attack resistance class B (locking system class C) according to DIN EN 1303

Execution:

- cylinder body and cylinder core made of solid brass (high corrosion protection)

- finish: dull nickel

- reversible key system

- horizontal key insertion

- cam 8-fold adjustable

- compatible with DOM electronics (made possible by integrating passive transponder technology into the key bow via a clip tag)

Key:

- key thickness: 2,6 mm

- nickel silver reversible key: corrosion-free and low-wear

- high operating comfort due to reversible key

- new key head design

- special high-low milling (lift-out and sloped areas) for optimal key insertion

- with additional stamped recess

- complex coding in the key makes it difficult to make a duplicate key (very high key copy protection)

- key blade length adapted to all common safety fittings

- no key blanks available on the market

Options / Special equipment:

- modular design with increased tear-off protection (through hardened steel bar)

- different cylinder finishes (on request)

- increased drilling protection (on request)

- weather protection (on request)

- freewheel (on request)

Operational area:

- for single- or multi-turn mortise locks and various other locks

- switch cylinder for elevator technology

- garage doors, key switches, activation devices, roller shutters (with side mounting)

- apartment buildings

- larger residential areas

- small and medium commercial objects

Scope of delivery:

- half cylinder incl. 3 or more keys

- 1 fixing screw

- Security card

Manufacturer:

DOM Sicherheitstechnik GmbH & Co. KG

Wesselinger Straße 10-16

D-50321 Brühl/Köln

www.dom-security.com

Reversible keys with special high-low milling (HT)

The DOM System ix Teco® (7TE) has a patented high-low milling in the key and thus offers a high technical key copy protection and high manipulation protection against opening techniques.

Impact protection

The cylinder contains impact protection pins and other security elements that prevent access by impact keys to turn the inner pins.

Opening protection

The cylinder contains specially shaped unlocking security pins that prevent opening with the help of a lock pick.

Pulling protection

The cylinder contains a special cylinder core which prevents the cylinder from being pulled out by drilling into the core.

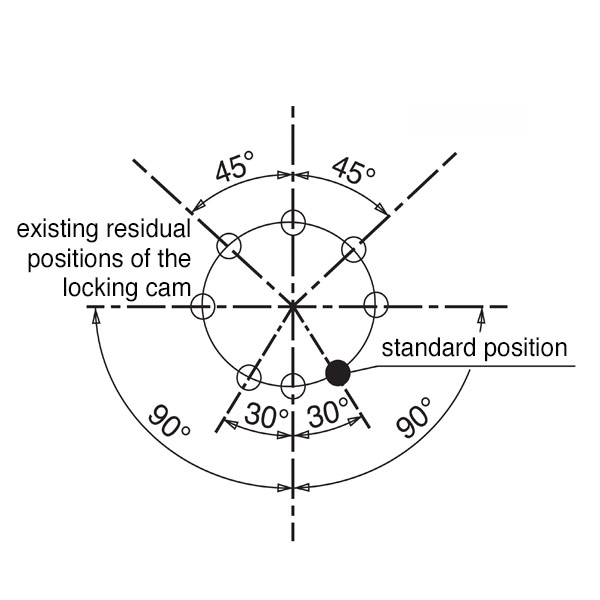

Cam position

The locking cam can be turned to 8 different locking positions (see white circles). The black circle represents the position at which the locking cam is positioned by default.

If you want to change the locking cam, it works as follows:

- Insert the key into the cylinder and turn the cam.

- Press the locking pin in the locking cam with a pointed object

(e.g. the DOM release needle or a thin slotted screwdriver) downwards towards the pressure spring. - Hold the key firmly and then turn the locking cam to the desired position.

- If the adjustment is successful, the locking pin can be heard to engage.

How to measure the cylinder length correctly?

Increased drilling and core pulling protection (on request)

The cylinder is provided with increased drilling and core pulling protection by means of carbide pins arranged in several planes in the cylinder body and cylinder core.

Cylinder finishes (on request):

- finishes (polished brass, oxidized bronze, matt black chrome)

- standard finish: dull nickel

- matt finish on the front side only

- for individual design requirements

- if desired, homogeneous appearance of door cylinder and fitting

If a different cylinder finish, different from the standard finish, is ordered, extended production times may occur.

dull nickel

polished brass

oxidized bronze

matt black chrome

Modular design

The modular cylinder is a profile cylinder in which the different cylinder lengths can be adjusted without great time expenditure by means of suitable intermediate parts of the respective locking system. This also protects against violent "tearing" and "pulling" on the cylinder (modular technology with increased tear-off protection).

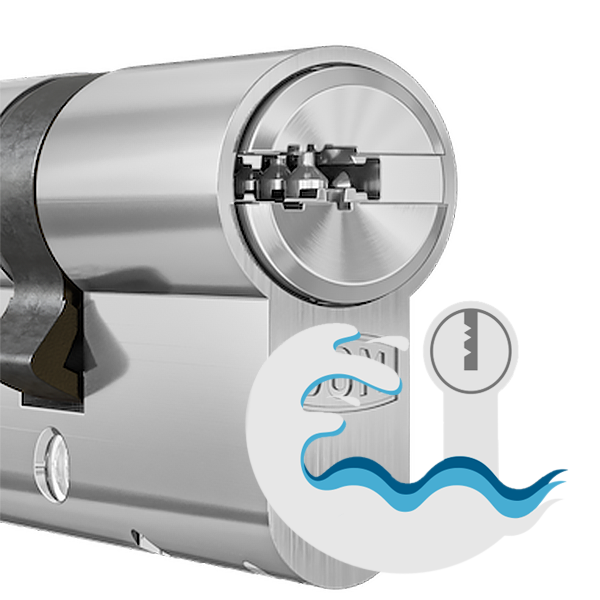

Seawater resistance (on request):

- for use in marine climate or salty atmosphere

- fixing screw pure brass, cam sintered steel (chemically nickel plated)

- cylinder finish: matt chrome

- restrictions possible in combination with other optional equipment

Freewheel (on request)

Freewheel cylinders are profile cylinders that have a freely rotating cam.

The cam can be moved freely through 360° when no key is inserted. DOM freewheel cylinders comply with DIN EN 18252:2006-12.

When the key is inserted, the spring-loaded clutch engages in the cam. The cylinder can then be locked in the conventional way with the key.

- from cylinder length: 35,5/35,5 mm

- Usually only necessary for special panic or automatic locks. If in doubt, please check with the door manufacturer.

- for multiple locking systems with panic function: latch and deadbolt must be moved into the body when the doors are closed. To ensure this, the cam must be able to turn freely.

- in motor-driven locks and special escape door locks

- restrictions possible in combination with other optional equipment

- this option cannot be combined with the emergency and danger function

- freewheel function is tested according to FZG (test guideline for profile cylinders with freewheel function for gear locks in escape door locks)